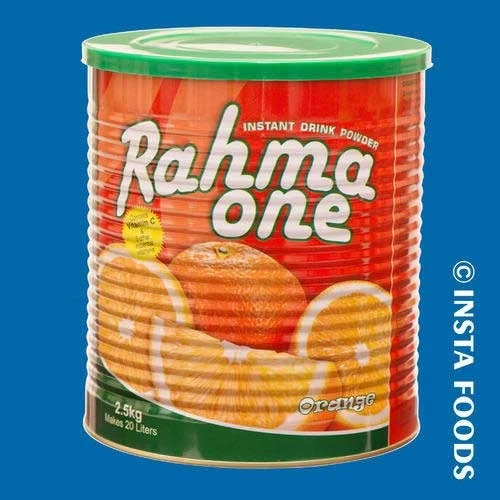

Flavors, specialty food ingredients, and FMCG items are all prepared and exported by our company name Insta Foods which has gained worldwide popularity. Some of Indias largest food, beverage, and pharmaceutical firms use our flavors and specialty food components to prepare their array. Our FMCG products are supplied under a private label to some of Indias largest retail chains and consumer product firms, as well as being exported to major retail chains, importers, and FMCG companies in Europe, the Middle East and Africa. Our manufacturer and supplier organization is led by a group of highly skilled technocrats with considerable senior management experience in the United States and India. They bring a total of five masters degrees from diverse disciplines, as well as over 55 years of technical skill and experience in the fields of food technology and chemical engineering. Over the last few years, a strong focus on research and development has resulted in the production of a wide range of distinctive and original goods such as Spray Dried Cheese Powder, Cardamom Flavor Powder, Spray Dried Palm Fat Powder, Vanilla Flavor, etc.

Specialized in making Non Dairy Creamer Powder, Medium Chain Triglyceride Powder, Lemon Flavour Soft Drink Powder, Instant Drink Powder, etc.

On April 1,

2011, the new company arose from the merger of its operations with its

parent company, Vin Flavors. Vin Flavors began making flavor emulsions

for the soft drink industry in 1978. It has created a variety of

encapsulated powder tastes and other specialty food components,

primarily for powder beverages, over the years. We began our career in

1990 by pioneering the creation and manufacturing of a line of powder

drinks for one of Indias largest beverage businesses. We have been

rapidly expanding since 2007, with the development of new products and

the increase of its consumer base. Most of the major unique materials

that go into our FMCG goods are made in-house, it was decided to unite

the two businesses to capitalize on the synergies of both.

In the years ahead, the united organization aspires to become one of the most dependable and leading providers of flavors, food components, and finished goods that meet worldwide standards.

Our Advantages

Quality Policy/ Process

Our products like Vanilla Flavor, Spray Dried Palm Fat Powder, Cardamom Flavor Powder, Spray Dried Cheese Powder, etc. are consistently rated higher in quality than those of our competitors. We are a technocrat-led corporation. An ex-quality controller in charge of the Coca-Cola India Region set up our quality systems and processes. The system set by him assures that our products meet the highest quality standards and conditions demanded by our clients.

Our commitment to quality begins with the buying process. All of our raw materials are sourced from reputable sources and thoroughly inspected before being used. We feel that the best method to preserve the quality of our products is to ensure that majority of the manufacturing processes are overseen by us. We directly supervise all crucial production steps. We also have quality control labs to ensure that all of our items are quality-tested before they leave our facility.

Manufacturing Facilities

Our cutting-edge facility is located 15 kilometers away from Baroda, Gujarat, India which is an industrialized area. We have facilities for the production of a variety of products such as Spray Dried Palm Fat Powder, Vanilla Flavor, Spray Dried Cheese Powder, etc. All active manufacturing and packaging areas are kept at a consistent temperature and an appropriate humidity level is maintained. Per shift, our facilities can handle around 3 MT of liquid, 6 MT of powders, and 1 MT of spray-dried components. We also offer pilot facilities for the development of flavor emulsions and a variety of spray-dried products.

In the years ahead, the united organization aspires to become one of the most dependable and leading providers of flavors, food components, and finished goods that meet worldwide standards.

Our Advantages

- We are technically proficient, which helps us in handling modern production machines.

- We have extensive product development experience in flavors, food ingredients, and consumable products.

- We are cost-effective and have a strong R&D that helps in an in-depth understanding of the food industry.

- Cross-functional expertise in a variety of culinary categories

- Customized packaging and products

Quality Policy/ Process

Our products like Vanilla Flavor, Spray Dried Palm Fat Powder, Cardamom Flavor Powder, Spray Dried Cheese Powder, etc. are consistently rated higher in quality than those of our competitors. We are a technocrat-led corporation. An ex-quality controller in charge of the Coca-Cola India Region set up our quality systems and processes. The system set by him assures that our products meet the highest quality standards and conditions demanded by our clients.

Our commitment to quality begins with the buying process. All of our raw materials are sourced from reputable sources and thoroughly inspected before being used. We feel that the best method to preserve the quality of our products is to ensure that majority of the manufacturing processes are overseen by us. We directly supervise all crucial production steps. We also have quality control labs to ensure that all of our items are quality-tested before they leave our facility.

Manufacturing Facilities

Our cutting-edge facility is located 15 kilometers away from Baroda, Gujarat, India which is an industrialized area. We have facilities for the production of a variety of products such as Spray Dried Palm Fat Powder, Vanilla Flavor, Spray Dried Cheese Powder, etc. All active manufacturing and packaging areas are kept at a consistent temperature and an appropriate humidity level is maintained. Per shift, our facilities can handle around 3 MT of liquid, 6 MT of powders, and 1 MT of spray-dried components. We also offer pilot facilities for the development of flavor emulsions and a variety of spray-dried products.